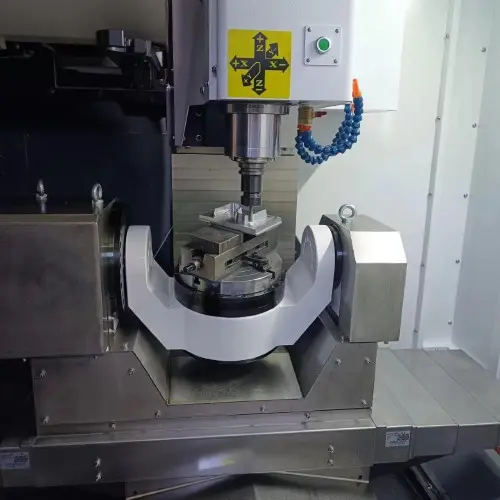

1.What is 5-Axis CNC Machining?

5-axis CNC machining is a sophisticated manufacturing process featuring two rotary axes and three linear axes, offering unparalleled precision and flexibility.

The three linear axes are:

-

-

- X-Axis: Movement from left to right across the work table.

-

- Y-Axis: Movement from up to down across the work table.

-

- Z-Axis: Vertical movement of the cutting tools.

Compared to a 3-axis machine, a 5-axis machine can move in two of three additional directions. These additional movements allow the machine to tilt and rotate the cutting tool or the part being machined, allowing more complex shapes and designs to be machined.

-

-

- A-Axis: Rotary motion along the X-axis.

-

- B-Axis: Rotary motion along the Y-axis.

-

- C-Axis: Rotary motion along the Z-axis.

2. Advantages of 5 Axis CNC Machines

-

-

- Enhanced Machining Quality and Efficiency

-

-

- Optimal Cutting Conditions: 5-axis machines maintain consistent contact between the cutting tool and the work surface, improving surface quality and reducing cycle times.

-

- Enhanced Machining Quality and Efficiency

-

- Improved Cutting Conditions

-

-

- Consistent Surface Quality: Rotating the table in multiple directions ensures optimal cutting conditions, resulting in superior finishes and greater accuracy.

-

- Improved Cutting Conditions

-

- Reduced Fixture Usage

-

-

- Single Setup Efficiency: Often, only one fixture setup is needed, eliminating additional fixtures and lowering costs and maintenance.

-

- Reduced Fixture Usage

-

- Streamlined Production Process

-

-

- Shorter Production Chains: Fewer setups simplify production management, reducing lead times and enhancing scheduling efficiency.

-

- Streamlined Production Process

-

- Advanced Technological Capabilities

- Complex Geometries and Precision: Capable of producing intricate shapes with minimal setups, 5-axis machines support faster production speeds and improved surface finishes.

-

- Versatility: They can machine five sides of a workpiece in a single setup, handle complex angles, and perform continuous milling operations, boosting productivity.

- Advanced Technological Capabilities